PRODUCTION

Engineering and Consulting

The department

The project dept. is equipped with a CAD-CAM system and a PLOTTER.

The system allows to tackle the study, the implementation and testing of prototypes based on the requirements of the customer.

This solution allows us to create realisations with a pilot cutting die in order to simulate a faithful industrial production.

IVAL technologies

The graphic layout of the items to be manufactured and the preparation of the framework for the printing operations are carried out on APPLE ® graphic stations.

The output of the offset plate utilizes the digital system Computer to Plate which operates on Heidelberg Suprasetter 162, fully automated.

PRODUCTION

Offset Printing

The department

Offset printing dept. is equipped with modern facilities to print 6 and 7 colours with water-based coating and UV varnishing devices in line.

IVAL technologies

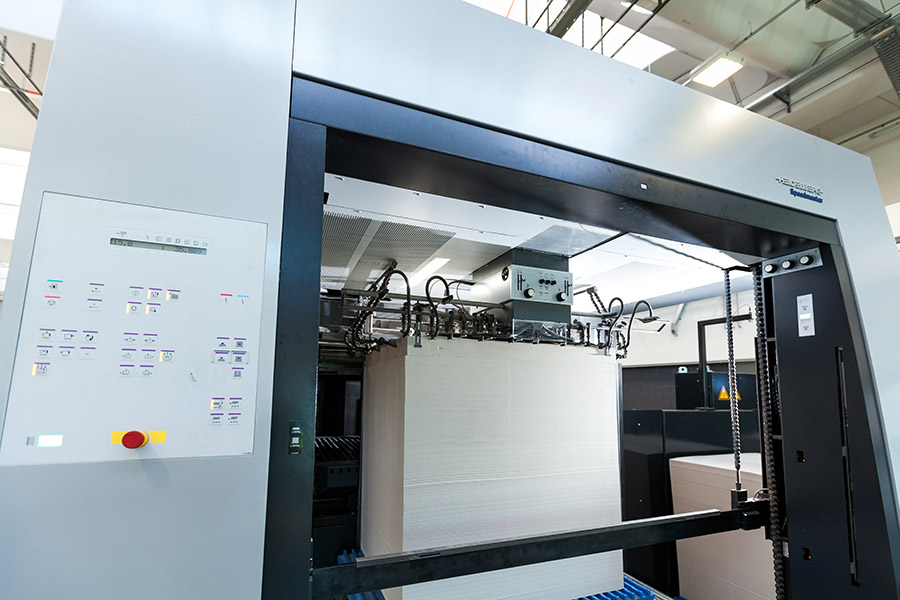

• Offset printing machine Heidelberg Speedmaster XL 145®

7-colours provided with water-based coating device LE and UV, maximum workable size 105 x 145 cm;

• Offset printing machine Roland® 906 6-colours provided with water-based coating LE, maximum workable size 100 x 140 cm;

• Offset printing machine Roland® 707 at 7 colours provided with UV coated device and double varnishing group in-line, in order to print paper/paperboard, laminated materials with metalized foils in PP / PET, direct printing on PP, PET, PVC, maximum workable size 78 x 104 cm.

The colour lab

The company is equipped with an internal laboratory for the preparation of any shades of ink (weighting system with high precision Mettler-Toledo®) Pantone® or according to client’s sample, with computerized verification of the final result by a station of analysis equipped with a spectrophotometer Gretag SPM55®.

PRODUCTION

Die cutting

The department

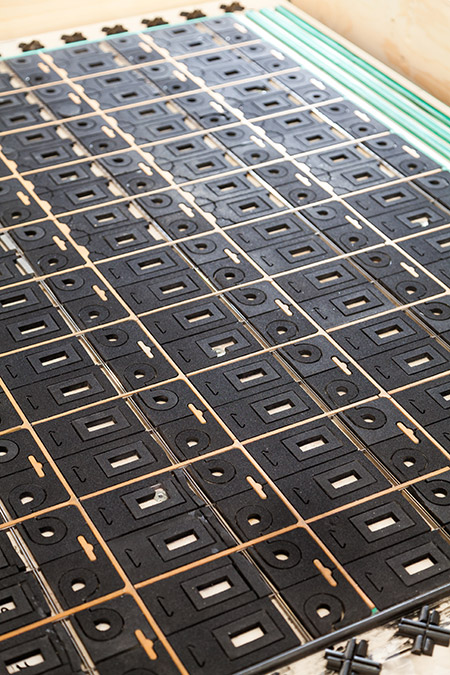

This departement is equipped with three Autoplatina Bobst® Group die cutter: two high production lines (sizes: 105 x 145 and 76 x 106) and a line in the format 100 x 140.

The project and testing of the equipment is executed internally using CAD-CAM equipment in order to have materials which are always and constantly updated and therefore suitable to the needs of high productive yield of the die cutting machines.

IVAL technologies

• Autoplatina® Bobst Mastercut 145 PER size 105 x 145 cm at high production;

• Autoplatina Bobst® Sprintera 106 PER in format 76 x 106 cm at high production;

• Autoplatina® Bobst SP 142 CER format 100 x 140 cm.

PRODUCTION

Final stage

The department

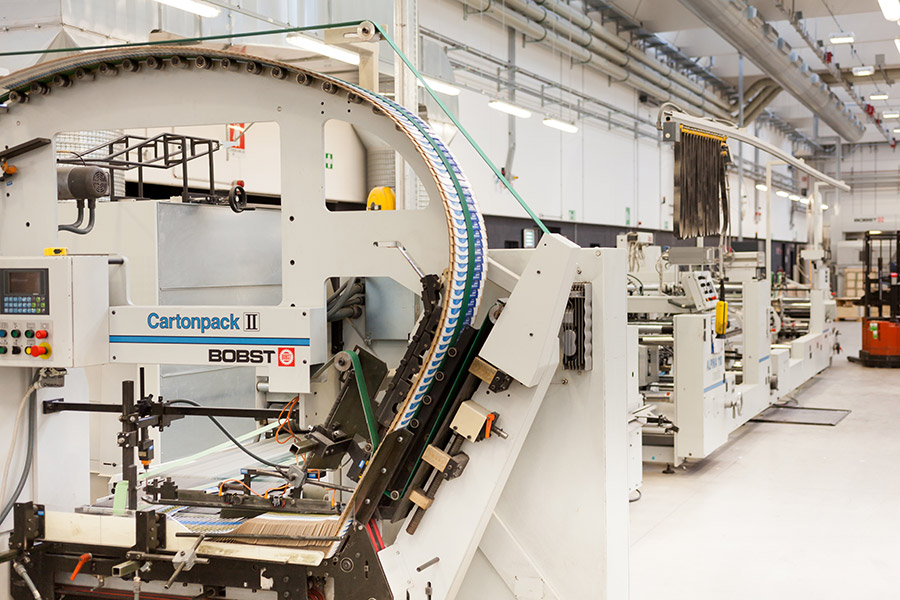

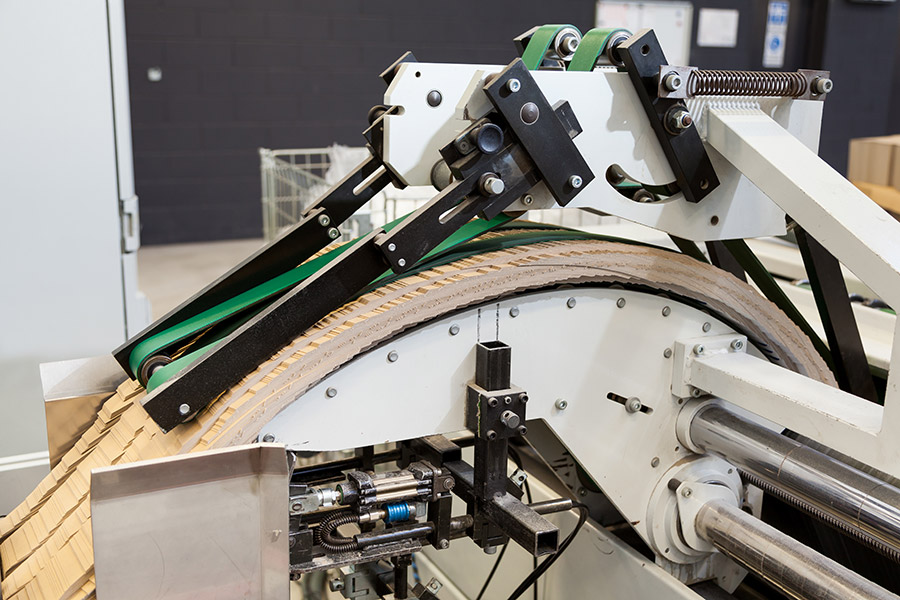

The gluing and packaging phase of the folding boxes is performed with window patcherse and folder-gluers of the latest generation at high productive yield.

IVAL technologies

• Window Heiber / Schröder® type "Matic" at high production with automatic roll change and final collector;

• Bobst® Alpina 110 type "Matic" folder gluer at high-speed provided with Cartonpack II ® for the collection and the automatic insert of the packs in cartons;

• folder-gluer JAGENBERG DIANA® 105/2 at high-production, for models at 4/6 corners or for automatic bottom packs;

• folder-gluer JAGENBERG DIANA® 74 at high-production;

• folder-gluer JAGENBERG DIANA® PRO 94 type "Matic" at high production.